ISSOKU - Automatic Tapped Hole Inspection Device | JSR GROUP

Bee-1

Automatic Tapped Hole Inspection Device

Automatic 100% inspection without any omission Dramatic reduction in the inspection time

|

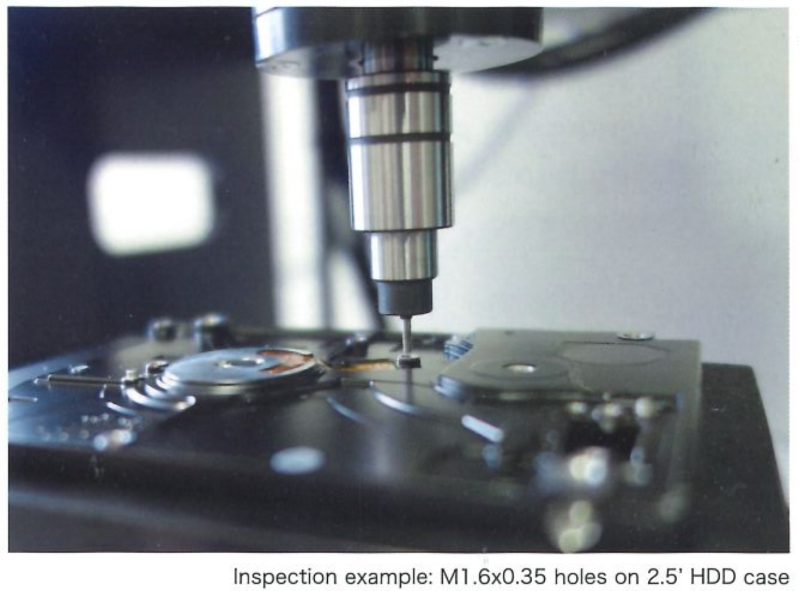

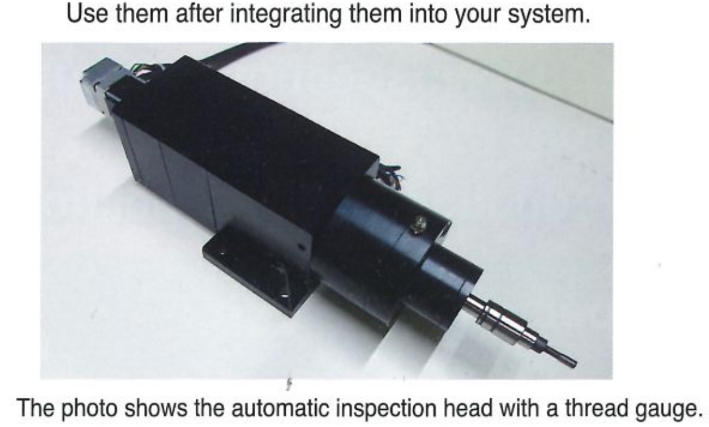

Quick inspection It takes only about 2 seconds to inspect a hole, thus significantly reducing the Inspection time (M1.4, depth 3 mm). Through setting the data for up to fifty spots, the user can continuous check threaded holes of different depths (for instruments with an XY positioning table). Floating mechanism (radial compensation, angular compensation) The floating mechanism ensures precise screwing motion regardless of the positional accuracy or inclination of holes. The system monitors the floating amount with a sensor to measure the depth of threaded holes with high precision. Inspection torque setting of your choice Conventional manual inspection using thread gauges can be automated, enabling the inspection at more stable torques. Inspection (screwing) torque can be set to best suit each product. Because the internal rotation resistance has been reduced to the minimum, the user can also select an ultra-low torque for micro screws and soft material products. Its plug gauge can be screwed out at high speeds and high torques, thus leading to a shorter inspection time The automatic inspection head and its controller are also available

Original internal structure (patent pending) and sensors Because the instrument precisely measures a threaded hole depth based on the screwing rotation angle, the pass/fall evaluation of the depth can be made with high reliability. (You can also inspect through holes). It flexibly supports switching to a small pitch thread. Inspections can be made with a no-go plug gauge, as well as with a go gauge.

|

Highly reliable thread plug gauge (patent pending) The incomplete thread is removed from its tip, which allows for precise measurement of depths while keeping smooth motion of the gauge. The dedicated gauge has eliminated the need for phase matching and position adjustments when the gauge is replaced because of wear or for other reasons. Special gauges can be made upon request. [Note] Use a thread gauge dedicated to the Bee-1. Otherwise, malfunction or defects may occur. System building From ten program settings of workpieces, the user can select a setting for one workpiece and load it to conduct threaded hole inspections of up to 50 spots per workpiece. As a manufacturer of measuring instruments, we develop and produce transferring machines and positioning machines that meet the specifications of our customers' products. The communication (I/O, RS-232C, and Ethernet) with external devices is optionally available |